Coke Business

Providing high-quality coke for Japan. And for the world.

Providing high-quality coke for Japan. And for the world.

The coke business has been core to Nippon Coke & Engineering for more than 70 years dating back to the 1950s. We have established our place as Japan’s leading manufacturer handling the manufacture and supply of coke—a fuel that is essential for making the iron and refining the non-ferrous metals that provide the foundation for a variety of industries.

Our high-quality blast-furnace coke and foundry coke—made using advanced material blending and firing technologies based on our long experience—have earned high marks, and we have customers for it both in Japan and overseas.

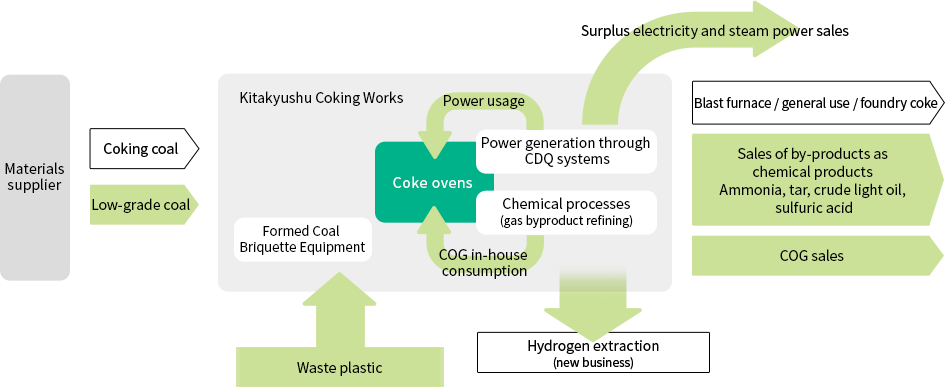

When it comes to our coke manufacturing process, we have created an ecological manufacturing process that recycles the energy used. For instance, we use COG gas derived from coking coal to fuel the manufacturing process, while for the electrical power of our plants we use electricity we generate ourselves from recovering the exhaust heat generated when extinguishing the coke.

Creating a recycling-oriented ecological manufacturing process that does everything possible to keep down its environmental load

In addition to being used as the heat source for melting iron ore in an ironworks’ blast furnace, it plays an important role as a spacer that guarantees a path for the reducing gas, melted iron, and reducing agents that remove the oxygen from the iron ore.

Type of coke used for generating the high calorific volume that serves as the heat source for melting metals when casting automobile engines and wheels as well as industrial machinery.

Used for a variety of purposes based on the granularity and quality of the coke, including for refining non-ferrous metals, lime burning, alloy iron production, and the production of all types of chemical products.

With its high calorific value and strength, in addition to being one of the two most important raw materials along with iron ore for producing iron, coke is also essential as a raw material for glass, for carbides, for zinc, and for refining the non-ferrous metals such as stainless steel. It provides a wide level of support to both manufacturing and everyday living.

Our search for ever higher-quality coke production technology naturally is an important issue for us, as is our quest to lessen our environmental impact. We are pursuing a variety of initiatives connected to reusing energy and reducing CO2 in the production process.

All coke ovens have CDQ system for heat recovery to quench the bright red coke from the coke oven. Recovered heat is changed to power and it covers all of the electric power needs of the facility, and the excess electricity is sold to Nippon Steel’s Kyushu Works.

We have installed and put into operation flue dust chambers in order to suppress the black smoke released while operating our coke ovens (Kitakyushu Coking Works). This equipment operates by removing soot from the exhaust gases to clean it before returning it to the chimneys. Through this, it reduces the environmental impact on the surrounding area.

This equipment that we have installed and put into operation introduces caking additives to the low-grade coal that is the basic ingredient of coke and then molds it in a forming machine, blending it with the ingredient coal to fixed ratio (Kitakyushu Coking Works). Blending the coal briquette means we can anticipate a reduction in what it costs to produce coke of a uniform quality, and also will lead to efficient production efforts owing to increased production of coke and various by-products.

PageTop